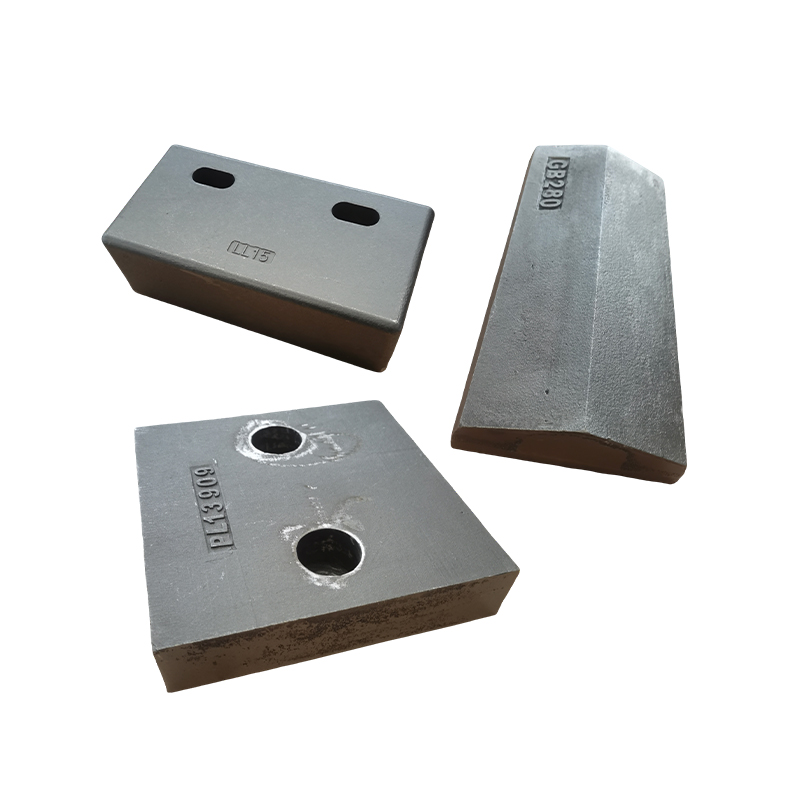

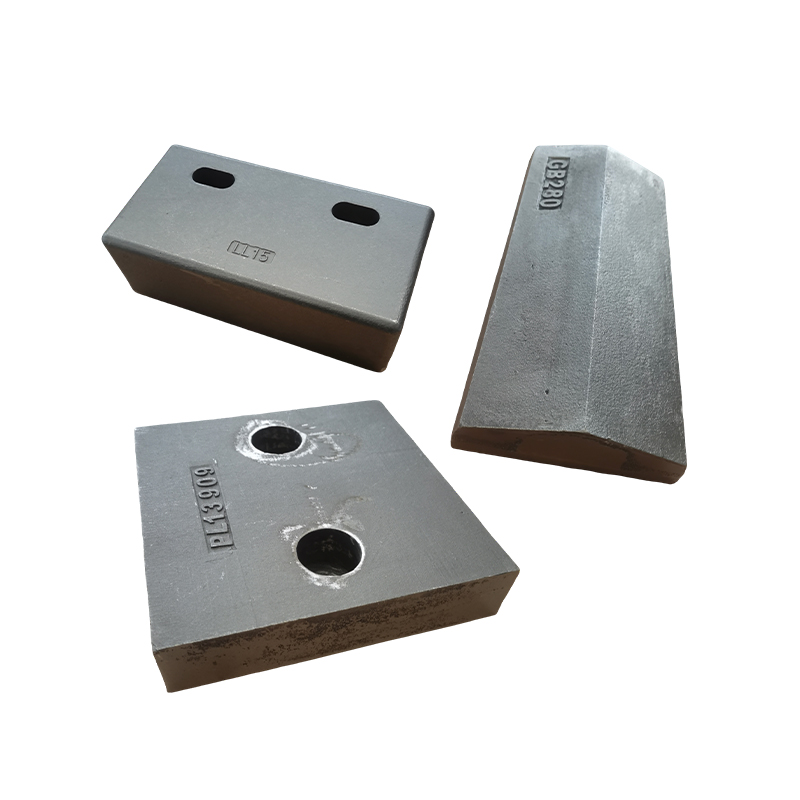

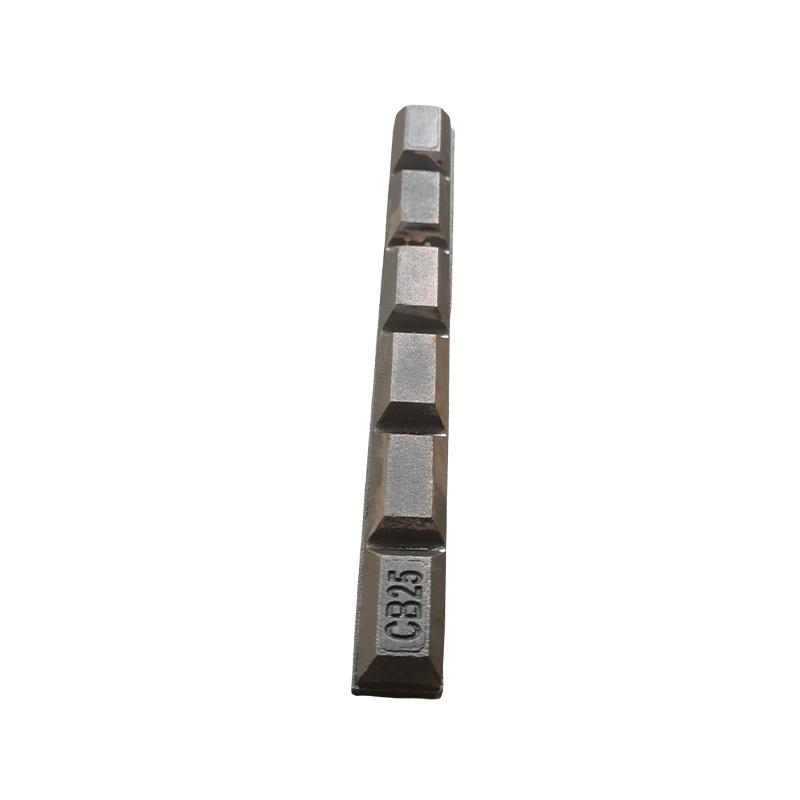

Deep in the mine shafts, in frigid open-pit mines, and in dust-filled crushing workshops, mining equipment endures extraordinary loads day after day: severe impacts, continuous vibrations, corrosive media, extreme temperature differences… These harsh cond

- +86-18073756333

- hnyrcl@163.com

- Oujiachong North Road, Eastern New Area, High tech Zone, Yiyang City, Hunan Province